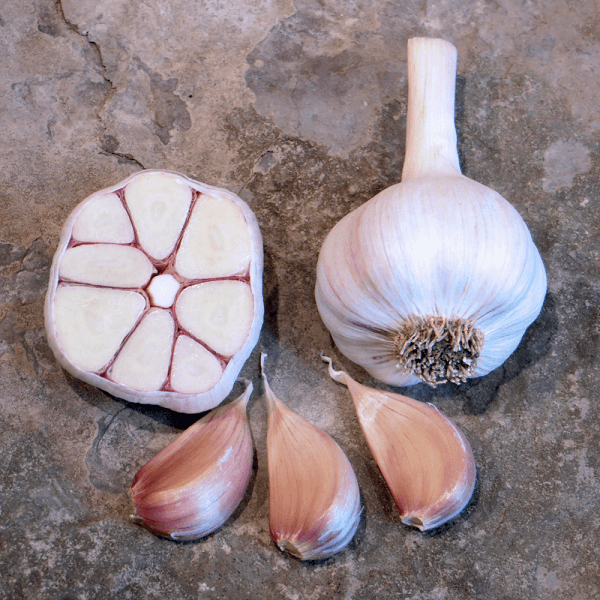

Garlic, this monocotyledonous plant that belongs to the onion subfamily, is one of the rich sources of protein. In traditional medicine, the use of garlic has been highly recommended to cure respiratory diseases, high blood pressure and high cholesterol, etc. Although the history of garlic consumption dates back to ancient Rome, today Iran is the leader in the production of this plant in the world. Every year, a large amount of Iranian garlic is exported to neighboring countries including Russia, Ukraine, Turkmenistan, Azerbaijan and Iraq. Every year, a large amount of agricultural products in Iran are lost due to storage in unusual conditions. Therefore, it is very important to know how to store garlic in the refrigerator and warehouse.

The way to store garlic changes according to its type, whether it is wet or dry, as well as the climate of its cultivation. The best thing to do is to reduce the temperature and dry the garlic immediately after harvesting it. In this way, you can minimize the entry of pests and pathogens into it. Also, it is better to disinfect the environment of your cold storage or warehouse before placing the garlic in it. The best way to store garlic is to put it in mesh bags with open holes for air to pass through. To keep dry garlic in the warehouse for a long time, it is better to use proper cooling systems. Adjust the temperature between 0 and 1 °C and the relative humidity between 60 and 70%. In this condition, garlic stays healthy for up to 8 months without sprouting. You can also store fresh garlic in the warehouse for 6 to 8 months at a temperature of about 16 degrees Celsius. So, in general, keep in mind that "proper ventilation" is one of the most important factors in maintaining its health and quality for keeping dry or fresh garlic in the cold room and warehouse.

Factors that must be observed in cold storage for agricultural and food products

Design and operational factors such as insulating surfaces, door protection devices, repeated use of the door, high cooling capacity, air cooling fan and coil designs, related control system design, air flow patterns, equipped and ready-to-use facilities, reserve for emergency cases such as breakdowns, layout Correct product

Time

In order to reach the maximum cooling, the product must remain in the refrigerator for a sufficient period of time. On the other hand, if this time exceeds the maximum storage period expected for a specific product such as additional moisture, the quality of the product will naturally decrease over time.

Temperature

If the refrigeration system does not have enough cooling capacity or cannot bring the temperature of the product to the appropriate temperature in the shortest possible time and keep it constant, it will cause the appearance of blisters, growth of eggs, change in color and taste, etc. .

Contact

Packaging containers with inappropriate design and materials, incorrect arrangement in pallets or box pallets, and not observing the distance between pallets, reduce the flow of cold air circulation and cooling speed.